As the Panda Hill mineralisation is relatively clean with low levels of impurities (particularly uranium, tantalum and titanium), and well liberated minerals at coarse grind, a flotation method can be used to process the niobium ore. The Panda Hill mineralisation is unique amongst Niobium projects currently under study in that this simple flotation, and non-complex hydrometallurgical process, can be used to upgrade the materials. Recovery in the first 10 years is estimated to be 60% with a 61% LOM recovery.

Standard grade ferroniobium (“FeNb”) makes up some 90% of world niobium consumption; the Panda Hill Niobium Project will produce standard grade ferroniobium, with the converter product (FeNb) being crushed, screened and packaged onsite to meet the specific customer demands. In general the sized product will be packaged in 1 tonne super-bags or 250kg steel drums, with some packaging into smaller 10lb or 25lb pails.

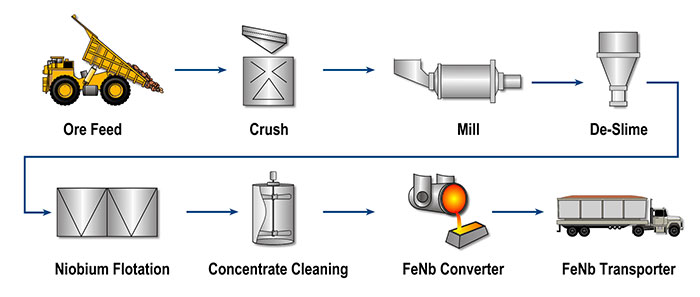

Stylised processing route for the Panda Hill Niobium Project. Panda Hill shares a similar processing path to the operating Niobec mine (Canada) and is fortunate to be able to utilise a low-cost single-stage flotation method.